-

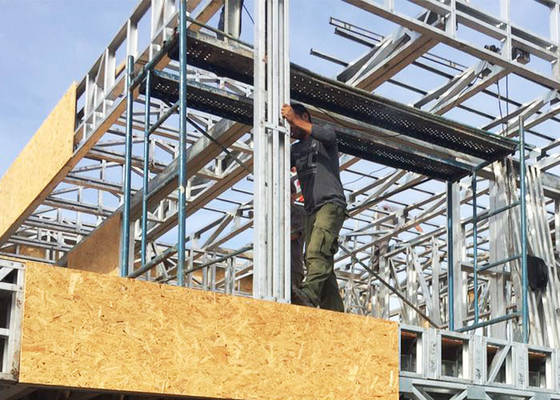

Prefab Steel House

-

Prefab Villa

-

Prefab House Kits

-

Portable Emergency Shelter

-

Prefab Garden Studio

-

Prefabricated Tiny House

-

Prefabricated House

-

Prefab Mobile Homes

-

Prefab Modular Homes

-

Prefab Bungalow Homes

-

Home Beach Bungalows

-

Overwater Bungalow

-

Light Steel Frame Houses

-

Australian Granny Flats

-

Metal Car Sheds

-

Prefab Apartment Buildings

-

Mobile Field Hospital

-

Cabin

-

Shawn EaganI enjoyed working with David. He was a hard worker and was easy to get along with. He always had a great attitude and seemed skilled at what he did.

Shawn EaganI enjoyed working with David. He was a hard worker and was easy to get along with. He always had a great attitude and seemed skilled at what he did. -

Denise NewmanDavid is a wonderful person to work with,he is always very responsive to our request and is prompt on delivery.We reccomend him anytime.

Denise NewmanDavid is a wonderful person to work with,he is always very responsive to our request and is prompt on delivery.We reccomend him anytime. -

Sean AghiliDavid is an outstanding owner who is very responsible, Knowledgeable, and prompt in responding to customers.

Sean AghiliDavid is an outstanding owner who is very responsible, Knowledgeable, and prompt in responding to customers.

Galvanized Steel Frame Sandwich Panel Prefab Light Steel Frame House Kits

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Frame Material | EPS Cement Wall Panels + Light Steel Frame/concrete Structure | Structure | Galvanized Steel Frame |

|---|---|---|---|

| Floor | Laminate/wooden/tile | Life Span | 100 Years |

| Roofing | EPS Sandwich Panel/steel Roofing/asphalt | Wall | Sandwich Panel |

| Installation | Instruct Installation,Provide Installation Video | Window | PVC Sliding Window |

| Door | Steel Door,Aluminum Alloy Door | Ceiling Material | CFC Board/ Gypsum Board+others |

| High Light | prefabricated house kits,modern prefab house kits |

||

Galvanized Steel Frame Sandwich Panel Prefab Light Steel Frame House Kits

Quick Detail:

| Name | prefabricated villa | Application | Villa for living |

| Color | white | Feature |

1.quickly to assemble on-site; 2.good earthquake proof; 3.green and energy save; |

| Material | light steel and other parts material | Certificate | CE,ISO,SAA,ETC |

Description:

Main structure: Light Gauge Steel

Wall material: ALC panel/fiber cement cladding+MGO board/gypsum board

Insulation material: Insulation material

Ceiling material: MGO board/gypsum board

Floor/foundation material: laminate flooring/wooden/PVC carpet

Door: steel security door/WPC or plywood door

Window: aluminum alloy/PVC

Roofing: EPS sandwich panel/steel roofing/asphalt shingle

Other fittings: toilet, washbasin, shower, kitchen, etc.

Lifetime: 100 years for structure

![]()

Applications:

House, Office, Villa, etc.

cost-efficient steel frame villa is made from a light steel framing system. the cladding is made by WPC. So it looks wooden house.

But this type of house is much more green and energy-saving than a normal wooden house.

The advantage of our wooden house kit is the following:

1. durable; the house can be designed for 100years lifetime

2. easy for assemble; the house can be erected within a couple of days

3. Green; Whole house is made of green material.

4. recyclable; 95% of house materials can be recycled.

5. low-carbon; It costs little energy to produce one house, save 90% carbon of traditional building;

6.earthqauke-proof: the house can resist over a 9-degree earthquake.

7.Cyclone-proof: the wooden house kit can be designed for 50m/s house

ISO standard light gauge steel for the main structure. fireproof, heat insulation, wind, and earthquake resistance.green, energy saving. also economically.

DEEPBLUE light steel system (advantages):

1. ENERGY Saving

The Wall and roof adopt new energy-saving and environmental material, making a Completely closed weatherproof system, avoiding the “Cold bridge” effect, small temperature changing, low heat conduction, and prominent energy saving effect which can meet the updated standard of over 65% energy-saving. When the outside temperature is 0℃, indoor temperature could keep 17℃at least, and when the outdoor temperature reaches 30℃, indoors is still 21℃. Compared with brick house, it can save money due to AC and energy charge, also can save power 30% at least from the AC energy expand in winter and summer, and the total embodied energy expands will save 30%.

2. Environment Friendly

During construction, the mainly dry construction is used at the working site, saving water.100% steel frame material is recyclable, above 80% other material is recyclable, reduces the environmental damage from the material; Also, CO2 emissions reduced 67% than a brick house; Meeting the energy-saving requirements.

3. Saving Floor Space

The wall thickness of our steel structure building is only half of the brick wall, so the usable floor area can reach 92%. Compared to the traditional brick, the floor area increases by 10%. Space can be divided freely with high utilization.

Design code:

(1)AISI S100 North American Specification for the Design of Cold-Formed Steel Structural Members published by the American Iron and Steel Institute (AISI) in the United States.

(2)AS/NZS 4600 Australian/New Zealand Standard-Cold-formed steel structures jointly published by Standards Australia and Standards New Zealand.

(3)BS 5950-5 Structural use of steelwork in building-Part 5. Code of practice for the design of cold-formed thin gauge sections published by BSI in the UK.

(4)ENV1993-1-3 means Eurocode 3: Design of steel structures; Part 1.3: General rules, Supplementary rules for cold-formed thin gauge members.

Production in DeepBlue factory:

![]()

![]()

![]()

How To Assemble:

![]()

Product Description:

DeepBlue earthquake proof prefabricated bungalow is based on a light gauge steel frame system with high-performance finishing materials. The whole house can be assembled within a couple of hours by 4workers.

the materials are the following:

1. Main structure: 89mm light gauge steel framing system based on AS/NZS 4600 standard.

the structure can be design to resist 50m/s wind and 9degree earthquake.

2. Roof structure: 89mm light gauge steel truss system.

3. Chassis: 89mm light gauge steel flooring chassis

4. flooring: 18mm fiber cement board with vapor barrier and bamboo flooring or wooden flooring, Pvc carpet, etc.

5.Wall cladding: 16mm PU insulated steel sandwich panel with beautiful decoration

6. interior lining: 9m fiber cement board, water-proof, termite-proof, security and healthy

7. ceiling: 8mm Pvc ceiling panel

8. insulation: 89mm glass wool insulation with good soundproof performance.

9.windows: PVC sliding windows

10.exterior door: high-quality aluminum sliding windows

11.interior door: painted wood door

12.bathroom: shower, washbasin, toilet included

13. roofing: corrugated steel roofing with the gutter system

14. veranda deck: W.P.C veranda flooring.

![]()

Specifications:

ISO standard steel structure house .one or two also three floors available. fireproof, heat insulation, wind, and earthquake resistance. green, energy-saving. economically.

Why Choose Light Gauge Steel Structure?

1)Lifetime for structure: 100 years.

2)Earthquake resistance: mix more than 8 grades.

3)Wind resistance:max 60m/s.

4)Fire resistance: all the materials used can be fire-resistant.

5)Snow resistance: max 2.9KN/m²as required

6)Heat insulation:100 mm in thickness can match 1 m thickness of the brick wall.

7)High acoustic insulation:60db of exterior wall 40db of interior wall

8)Insect prevention: Free from the damages by insects, such as white ants

9)Ventilation: a combination of natural ventilation or air supply keep the indoor air fresh and clean

10)Packing and delivery: 140SQM/ 40'HQ container for structure only and 90SQM/ 40'HQ container for structure with decorating materials.

11)Installation: the average is one worker one day install one SQM.

12)Installation guide: dispatch engineer to guide on site.

Design code:

(1)AISI S100 North American Specification for the Design of Cold-Formed Steel Structural Members published by the American Iron and Steel Institute (AISI) in the United States.

(2)AS/NZS 4600 Australian/New Zealand Standard-Cold-formed steel structures jointly published by Standards Australia and Standards New Zealand.

(3)BS 5950-5 Structural use of steelwork in building-Part 5. Code of practice for the design of cold-formed thin gauge sections published by BSI in the UK.

(4)ENV1993-1-3 means Eurocode 3: Design of steel structures; Part 1.3: General rules, Supplementary rules for cold-formed thin gauge members.

![]()

Resistant to various weather conditions, due to its light gauge steel framing system, DeepBlue Mobile Homes can resist winds up to 50m/s, 50cm snow loads as well withstand earthquakes due to its special steel structure technology.

The DeepBlue Mobile Houses manufacturing technology is truly a mature product characterized by flexibility and innovative design and solution.

![]()

![]()

Based on our patented foldable technology, transportation and erection can be done in a very simple and convenient way in order to save lots of time, energy, and unnecessary expenses.

Your first choice, Deepblue Prefabrica